- Search

- Login

- Quote Cart

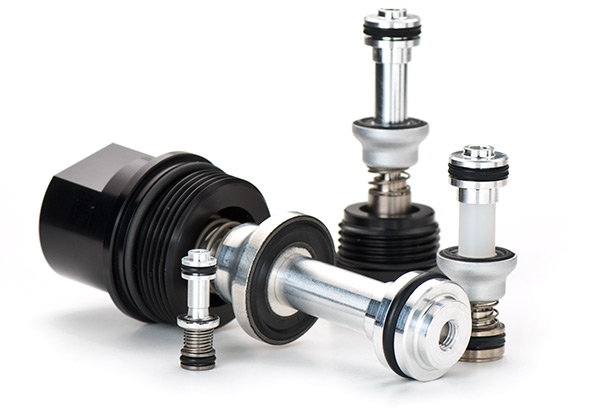

For 15 years, NGT has been supplying a diverse selection of specialty valves that provides our customers with greater flexibility when it comes to design. We are also dedicated to increasing the quality of our product through continuous testing and redesign.

The testing improves our ability to provide greater engineering information to our customers and helps us determine the limits of our product. Send us a sketch or a description of your request and we will get back to you within 12 hours. NGT will only work on a limited number of customer requests simultaneously in order to make sure the project is completed on time.

The balanced check has been cycle tested without lubrication for 10 million cycles with no sign of wear or failure. Most ball or poppet type check valves that lock pneumatic cylinders in position, require high opening forces. Forces wear on the valve each time it's cycled. A balanced design increases valve life by reducing operating forces. With air trapped behind the poppet (output side), the checked piston tries to pull the poppet off its seat. Slightly increasing the pressure area behind the poppet makes it larger than the piston area, and partially biases the poppet to its seat. With pressure applied to the pilot, the force required to open the poppet is the small difference in pressure between poppet and balancing piston.